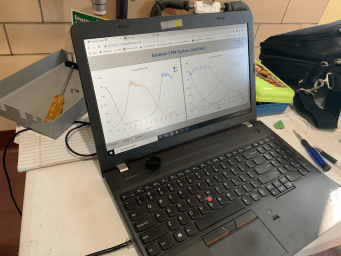

Machinery Monitoring System’s Sentinel®-CPM (Compressor Performance Monitor) was designed to provide “Real Time Compressor Health and Safety Monitoring”. Calculations, including Horsepower, Rod Loads, Theoretical Temperatures, and Flows, utilizing ACI’s state-of-the-art eRCM Kernel calculations and algorithms that are tailored to the individual machine. The MMS Compressor Diagnostics Program is also installed on every MMS Sentinel – CPM. NO monthly subscription fees or having to upload your sensitive data to a 3rd party web application in the Cloud.

Sentinel – CPM Key Features

- Real time HP for each cylinder end

- Real time measurements and alarming of rod loads and degrees of reversal

- Automated leak detection of suction & discharge valves, rings and packing

- Quickly alarm on Load Step or clearance pocket issues

- eRCM Kernel enhanced with MMS real time compressor performance calcs

- Changeable Usernames, Encrypted Passwords and Multi-Factor Authentication per TSA mandates

- Continuous monitoring of up to 6 double-acting compressor cylinders (up to 12 cylinders w/ an additional CPM module

- 12 pressure sensor inputs

- 2 Magnetic Pickup inputs (TDC & Deg)

- MODBUS (RS-485 & Ethernet) communication

- Class I, Division 2, Gas groups A, B, C & D

- Alarm Relay – Dry contacts

Sentinel – CPM Calculations

- Cylinder-End HPs

- Suction/Discharge Pressures

- Suction/Discharge VEs

- Rod Reversal/Loads

- Theoretical Discharge Temperatures

- Flows & Flow Balances

- Flow Profile Algorithm

- OEM Methods and Limits Used

- Theoretical PV Cards

- Calculated Clearances

- Interstage Pressure Predictions

- Gas Leakage Rate

The Sentinel – CPM Compressor Diagnostics Program can reliably detect the most common reciprocating compressor faults in real time. We will continue to expand our fault detection to other serious but less common reciprocating compressor issues as we continue to refine this product.

Our motto, our customers come first is reflected in this new product. We are proud to share that our MMS Compressor Diagnostics program is installed on every MMS Sentinel – CPM board and connects directly to the Unit PLC to exchange data. This is a big win for our customers and best of all, there are no monthly subscription fees nor data that has to be uploaded to a company’s web application in the cloud.

Detected faults include:

• suction valve leaks

• discharge valve leaks

• rings leaks packing leakage

• unloader and clearance pocket issues overloading the compressor

• exceeding rod load limits

• lack of rod reversal